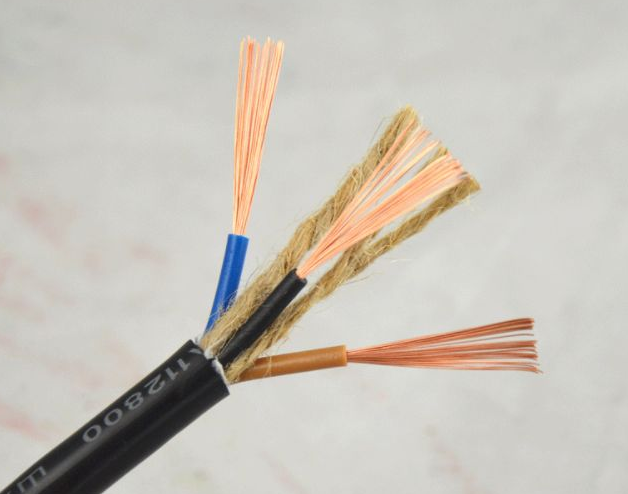

1. Remove the outer sheath and main insulation layer of submersible pump cable, expose the copper wire to 35-40mm, trim the rubber near the core, polish the oxide layer on the core, and wipe the submersible pump cable core and insulation layer and sheath layer with alcohol (preferably hydrochloric acid) to let it dry naturally.

1) power cord 2) PVC tape 3) self-adhesive butyl tape 4) 1mm copper wire 5) solder 6) lead cable

3. Prepare 500W soldering iron, rosin, soldering tin, LMM bare copper wire and insulating tape.

4. Tighten the cable core evenly with bare copper wire of submersible water pump cable, heat and permeate tin with electric soldering iron, and require infiltration and penetration. Repair the flat welded part with a file (no burrs or sharp objects are allowed), then wipe the part to be re-wrapped with alcohol and let it dry.

5. First, use self-adhesive butyl tape to laminate three layers and gradually extend to the outside of the core. When packing, the tape must be stretched 200%, then the submersible water pump cable is laminated with three layers of PVC tape and gradually extends outward to ensure that the packaging part is not less than 200mm.

6. When connecting the three-core cable connector, the positions of the three connectors should be moved a certain distance to prevent short circuit.

1) after the cable is connected, shake the insulation resistance of the cable and the motor (without adding water), and the value shall not be less than 150 megohm. 2) shake the motor again after water injection. The insulation resistance of the motor winding should not be less than 40 megohm. 3) turn on the power for test (no more than 2 seconds). Make continuous position markers

Enterprise qr code

Website qr code